Descrizione del prodotto:

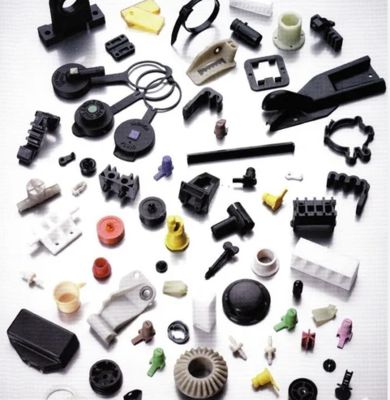

Una parte stampata per iniezione di nylon è un tipo di prodotto che viene fabbricato utilizzando uno stampo per iniezione, in particolare uno stampo a cavità singola.Questo particolare prodotto è stato creato attraverso il processo di plastica stampaggio ad iniezione, in cui il materiale di nylon fuso viene iniettato in una cavità dello stampo per formare la forma desiderata.

Lo stampo a iniezione utilizzato per la produzione di questa parte a iniezione di nylon è dotato di un sistema di raffreddamento ad acqua, che aiuta a regolare la temperatura dello stampo durante il processo di produzione.garantire un raffreddamento costante ed efficiente per una qualità ottimale delle parti.

Inoltre, lo stampo è stato progettato come uno stampo per iniezione di plastica, su misura per le esigenze specifiche di stampo di materiale di nylon.Lo stampo è personalizzato in dimensioni per adattarsi alle dimensioni della parte plasmata da iniezione di nylon, garantendo la precisione e la precisione del prodotto finale.

Per quanto riguarda la finitura superficiale del pezzo stampato a iniezione di nylon, esso subisce un processo di lucidatura.fornire una finitura liscia e lucida che soddisfi gli standard di qualità e migliori l'aspetto estetico generale del prodotto.

Lo stampo utilizzato per creare la parte plasmata a iniezione di nylon è progettato per una durata di vita di 100.000 colpi.mantenere una qualità costante della parte e un'efficienza di produzione per un periodo di utilizzo prolungato.

In sintesi, la parte plasmata a iniezione di nylon è prodotta utilizzando uno stampo a iniezione specializzato con un sistema di raffreddamento ad acqua per un controllo efficiente della temperatura.è personalizzato in dimensioni per soddisfare i requisiti specifici del materiale di modellazione del nylonLa parte presenta una finitura superficiale lucida e lo stampo è costruito per durare 100.000 colpi, garantendo affidabilità e qualità a lungo termine nella produzione.

Caratteristiche:

- Nome del prodotto: parte dello stampo a iniezione

- Finitura superficiale: lucidatura

- Cavità della muffa: 1

- Sistema di espulsione di muffe: pin di espulsione

- Nocciolo di muffa: P20

- Dimensione della muffa: personalizzata

Parametri tecnici:

| Dimensione della muffa |

Personalizzato |

| Tolleranza |

0.01 mm |

| Tipo di porta di muffa |

Porta sottomarina |

| Sistema di raffreddamento della muffa |

raffreddamento ad acqua |

| Sistema di espulsione della muffa |

Pini di espulsione |

| Tipo di muffa |

Moffa per iniezione di plastica |

| Numero di cavità |

Non sposato |

| Sistema del corridore |

Corridore caldo |

| Vita della muffa |

100Mille colpi. |

| Base della muffa |

LKM |

Applicazioni:

Gli stampi a iniezione LANMON sono strumenti versatili progettati per produrre parti a iniezione di nylon di alta qualità con precisione.questi stampi sono dotati di un sistema di raffreddamento ad acqua per garantire un'efficiente dissipazione del calore durante il processo di stampaggio.

Personalizzati per soddisfare esigenze specifiche, i stampi a iniezione LANMON sono dotati di una singola cavità, che li rende ideali per la produzione di pezzi individuali con dettagli complessi.Il sistema di scarico a caldo incorporato in questi stampi aiuta a mantenere un controllo costante della temperatura, che si traduce in una qualità uniforme delle parti.

Lo stampo a iniezione LANMON è adatto a una vasta gamma di occasioni e scenari di applicazione grazie alla sua adattabilità e affidabilità.componenti per autoveicoli, parti elettroniche o dispositivi medici, questo strumento di stampaggio a iniezione di precisione fornisce risultati costanti e precisi.

Con la sua robusta costruzione e il suo design a cavità singola, i stampi a iniezione LANMON sono perfetti per la prototipazione di nuovi prodotti o la produzione di piccoli lotti di parti specializzate.L'ingegneria di precisione di questi stampi garantisce che ogni parte plasmata a iniezione di nylon soddisfi le specifiche esatte richieste dal cliente.

Sia che si tratti di una geometria complessa o di un design semplice, gli stampi a iniezione LANMON possono gestire una varietà di dimensioni e configurazioni di stampo con facilità.Il sistema di raffreddamento ad acqua aiuta a mantenere temperature di funzionamento ottimali, prolungando la vita dello stampo e riducendo i tempi di fermo di produzione.

In sintesi, gli stampi a iniezione LANMON sono la scelta ideale per i produttori in cerca di affidabilità, precisione ed efficienza nei loro processi di stampaggio.Questi stampi eccellono nella produzione di parti stampate a iniezione di nylon di alta qualità per una vasta gamma di industrie e applicazioni..

Personalizzazione:

Servizi di personalizzazione del prodotto per il prodotto di parti di stampi a iniezione:

Marchio: LANMON

Numero di modello: NONE

Luogo di origine: CINA

Dimensione della muffa: personalizzata

Cavità della muffa: 1

Sistema del corridore: corridore caldo

Materiale: acciaio

Tipo di muffe: muffe per iniezione di plastica

Parole chiave: Componente stampato su misura, Stampo multi cavità, Componente stampato su misura

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!